In use since the late 1940s, diisocyanates are a family of chemical building blocks mainly used to make polyurethane products, such as rigid and flexible foams, coatings, adhesives, sealants and elastomers. Many of the products we rely upon every day are safer and more comfortable through the use of polyurethanes made possible through diisocyanates.

Polyurethane chemistry is complex, but the basics are relatively easy to understand. Polyurethanes are produced by combining diisocyanates with polyols and other chemical additives. Because a variety of diisocyanates and a wide range of polyols can be used to produce polyurethane and the speed of the reaction can be adjusted, a broad spectrum of materials can be produced to meet specific application needs. Diisocyanates are important in the production of countless products, particularly in the transportation and construction industries.

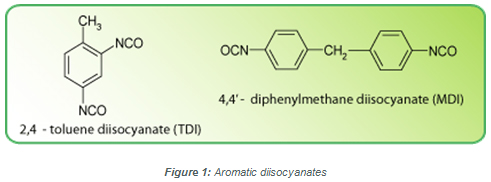

Aromatic Diisocyanates

Diisocyanates used in polyurethane production are divided into two types: aromatic diisocyanates and aliphatic diisocyanates.

There are two primary aromatic diisocyanates: toluene diisocyanate (TDI) and methylenediphenyl diisocyanate (MDI). TDI is used primarily in the production of flexible foams. MDI, the second type of DII, comes in two forms: Pure MDI and polymeric MDI (PMDI). Pure MDI is used in the production of a variety of polyurethane products like elastomers, sealants, adhesives and coatings. PMDI is a highly versatile product used to produce a wide variety of rigid, flexible, semi-rigid and polyisocyanurate and thermoset foams.

There are also less common aromatic diisocyanates, such as p-phenylene diisocyanate (PPDI) and naphthalene diisocyanate (NDI).

What Is TDI?

Toluene diisocyanate (TDI) is a chemical used in the production of polyurethanes, primarily for flexible foam applications including furniture, bedding and carpet underlay, as well as packaging applications. TDI is also used in the manufacture of coatings, sealants, adhesives and elastomers. In transportation applications, TDI helps produce lighter automobile parts, saving weight, which leads to improvements in fuel efficiency and thus energy conservation.

From a technical perspective, TDI is obtained by nitration of toluene. The hydrogenation of dinitrotoluene is then obtained to produce toluenediamine (TDA), which is in turn reacted with phosgene to form TDI.

What Is MDI?

Methylenediphenyl diisocyanate (MDI) is a chemical used in the production of polyurethanes for many applications. MDI is used primarily in the production of rigid polyurethane foams used for insulation for your home or refrigerator, and many other uses. Insulation made with MDI can help consumers save on their heating and cooling costs and conserve energy. Some additional uses of MDI in polyurethanes include coatings, adhesives, sealants, and elastomers found in items such as paints, glues, and weather resistant materials. It is also used to make many types of footwear, sports and leisure products and to a much lesser extent, some specialty flexible foams. MDI can also be used as a binder for wood and to produce mold cores for the foundry industry.

From a technical perspective, MDI is obtained from the condensation of aniline with formaldehyde to produce methylene dianiline (MDA), which is in turn reacted with phosgene to form MDI.

Chemical Composition of the Aromatic Diisocyanates TDI and MDI

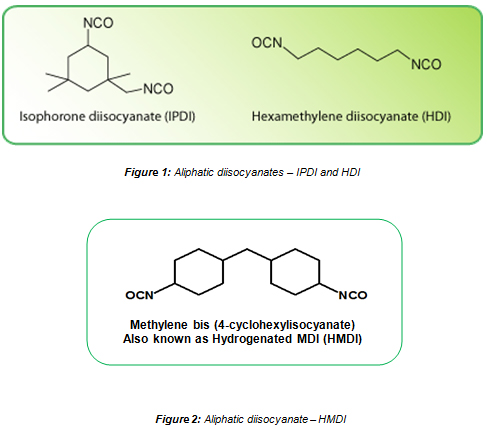

What Are Aliphatic Diisocyanates?

Diisocyanates, including the specific subset of diisocyanates called aliphatic diisocyanates, have been used since the late 1940s and have been extensively studied. Aliphatic diisocyanates, such as hexamethylene diisocyanate (HDI), methylene dicyclohexyl diisocyanate or hydrogenated MDI (HMDI) and isophorone diisocyanate (IPDI), are often further reacted to form polyisocyanates, which act as building blocks to form color-stable polyurethane coatings and elastomers.

Chemical Composition of the Aliphatic Diisocyanates: IPDI, HDI and HMDI