#CleanWater: Brought to You by Chemistry

ACC celebrates #WorldWaterDay and the White House Water Summit by releasing a video highlighting the many ways chemistry keeps water flowing—from source to tap.

Chlorine chemistry helps conserve energy and water resources by delivering clean drinking water through sustainable PVC pipe.

Beneath our cities and towns a complex network of pipes deliver a life-sustaining fluid to homes, schools and businesses. Like the veins and arteries of the human circulatory system, the infrastructure below our feet conveys an essential fluid where it is needed and carries waste products away. The fluid is clean water, of course, and many of the pipes are, well…leaking.

The

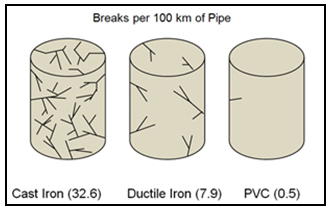

Watermain Break Clock tracks the estimated number of watermain breaks in the U.S. and Canada since January, 2000. At the rate of 700 per day, the number of breaks is now in the millions. One study found leakage from metal pipes costs U.S. consumers about $3 billion per year. Increasingly, aging and corroded buried water pipes are being replaced with durable, long-lasting polyvinyl chloride (PVC) pipe, made with chlorine chemistry. Pipes made of traditional materials are subject to fracturing and degradation. PVC pipe can remain maintenance-free for up to 100 years, making it a smart choice for state and federal infrastructure renewal projects.

A Peak through the Pipeline of History

Water delivery through pipes has been around for thousands of years. According to

SewerHistory.org, the earliest pipes were made of stone or clay. Lead pipes constructed by the Roman Empire, were an unfortunate choice and may have shortened life expectancy in ancient Rome. Later materials included cast iron, wood and concrete. Early American settlers used bored-out logs of hemlock or elm1 to convey water.

As urban populations grew and the demand for water increased, cities began using pipes of cast iron, starting with Philadelphia in 1804. Ductile iron, invented in 1943, was seen as an improvement in metal pipe technology because of its greater strength and ability to be stretched and molded. The first PVC pipes were manufactured in Germany in 1935. PVC pipe came to the U.S. in 1952, and by 1985, the 750,000th mile of PVC rural water pipe had been installed. According to a recent economic analysis of PVC, the great majority of large diameter water and sewer pipe installed in the U.S. and Canada is made of PVC, a tribute to its low cost, ease of installation and reliability.

PVC Pipe: Environmental Benefits

Durable, corrosion-free PVC pipe stands the test of time, all the while conserving precious drinking water and reducing or eliminating the need for repair and maintenance. But there are a few other attributes that place PVC pipe squarely in the category of sustainable products.

The smooth internal surface of PVC pipe resists mineral and biological deposits that constrict water flow and harbor disease-causing microorganisms. It has been estimated that a three millimeter-thick internal scaly deposit can double the energy needed to pump water. PVC is hydraulically smooth, resisting scale and preserving high-flow efficiency. And, as a lightweight plastic, PVC can be transported to installation sites using less energy than is required to transport traditional metal or concrete pipes. Installation is relatively quick and easy.

According to the American Society of Civil Engineers, “Deferring investments in infrastructure renewal and maintenance has put the health, safety, and welfare of the public at risk, impeded economic growth and competitiveness, and lowered the quality of life.” As we begin to address America’s aging water delivery system, it is likely that PVC pipe will play an essential role in its revitalization.

The Challenge of Biofilms

Using today’s powerful microscopes, scientists are unlocking the secrets of biofilms. A biofilm is a complex colony of bacteria attached to a wet surface. We are all familiar with biofilms. They include the slippery coatings on rocks in streams and the cavity-causing plaque on teeth. These mini-ecosystems also form obstructions on the rough interiors of metal and concrete water pipes, raising the risk of drinking water contamination. Fortunately, the smooth interior surface of PVC pipe is resistant to biofilm formation.

Biofilms “glue” themselves to surfaces using a slimy polymer excreted by bacteria. The bacteria in biofilms obtain their energy from organic matter that washes over the surfaces to which they are attached. Under favorable conditions, biofilms can grow and develop in complexity, becoming more microbially diverse and resistant to disinfectants. We now know that within the biofilm environment, bacteria find strength in numbers and use novel ways to communicate to enhance their odds of survival. As researchers learn more, we will be increasingly better equipped to avoid exposure to those biofilms that represent a threat to public health.

1

http://www.theplumber.com/usa.html