Fiber optic technology is revolutionizing the fast-paced world of communications, delivering digital information through hair-thin strands of ultra-pure glass. Chlorine chemistry is essential to producing high-purity fiber optic glass.

A Light Revolution

Fiber optic technology is revolutionizing the fast-paced world of communications, delivering digital information through hair-thin strands of ultra-pure glass. Telephone, Internet and cable TV signals, once transmitted only as electrical signals through bundles of metal wire, now course through glass fibers as pulses of light.

Chlorine chemistry has a role in producing the high-purity glass of optic fibers. It is estimated that American and Canadian consumers save $2.5 billion on fiber optics applications each year, thanks to a smart, recyclable use of chlorine chemistry.

Move Over, Metal Wire

Optic fibers offer many advantages over traditional metal wires, including greater energy efficiency, lower cost, a clearer signal and lower fire hazard. Optic fibers transmit data at speeds of over 10 gigabytes per second compared to 1.5 gigabytes per second through metal wire.

Transmitting the signal for your favorite TV show as pulses of light through optic fiber is very different from sending it as an electrical signal through copper wires. Electrical signals are carried through metals, such as copper, in the form of flowing electrons—tiny, sub-atomic, negatively charged particles.

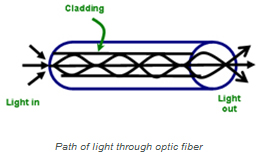

In contrast to electricity, fiber optic technology employs light energy. Each glass optic fiber is enclosed in an internally mirrored tube, known as “cladding.” Depending on the width of the fiber, light travels through the high-purity glass thread in either a straight (very thin fiber) or a zigzag (thicker fiber) pattern. As the illustration shows, light bounces off the mirrored cladding as it hurtles toward its destination. The extreme purity of the glass and the high reflectivity of the cladding help prevent the signal from degrading.

In contrast to electricity, fiber optic technology employs light energy. Each glass optic fiber is enclosed in an internally mirrored tube, known as “cladding.” Depending on the width of the fiber, light travels through the high-purity glass thread in either a straight (very thin fiber) or a zigzag (thicker fiber) pattern. As the illustration shows, light bounces off the mirrored cladding as it hurtles toward its destination. The extreme purity of the glass and the high reflectivity of the cladding help prevent the signal from degrading.

Chlorine's Role in Fiber Optics

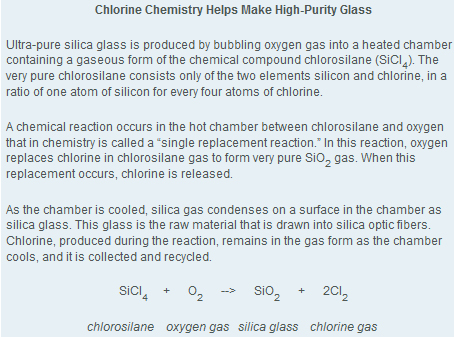

Chlorine chemistry is essential to producing high-purity fiber optic glass. Like window glass, fiber optic glass is a clear solid made of silicon and oxygen in a 1:2 mix (SiO2, silicon dioxide, aka “silica”). Unlike window glass, fiber optic glass is not much else; that is, it is very pure. This is a “must” in fiber optics because impurities would interfere with the transmission of the light signal, absorbing some of it and changing carefully planned paths of reflection along the cladding. Almost all high-purity glass for optic fiber is made from silica, which is purified using chlorine chemistry.

Breaking News: Bending Optic Fibers

Until recently, the light signal through optic fiber degraded as the fiber was bent. A perfectly straight length of fiber would transmit the full light signal, but bending the fiber would cause some of the light signal to escape, and coiling it tightly would cause a complete loss of signal. Now Corning researchers announced they have developed a cladding that enables light signals to be transmitted fully through sharply bent and even coiled fiber. According to the Corning scientists, they have devised a kind of guardrail structure on the nano-scale (a nanometer is one billionth of a meter) that keeps light pulses on track, rushing through the very pure glass, regardless of whether the fiber is tightly wound or perfectly straight.