What do cold water detergents, catalytic converters, and fertilizer have in common? They all rely on a powerful technology called catalysis. Catalysts are added substances that increase the rate of a chemical reaction. As a result, less energy is used per unit of product.

In many ways, catalytic processes and technologies make modern living possible. Reduced emissions in modern cars, pharmaceutical breakthroughs that improve health, increased yield in food production and energy-saving laundry detergents are all made possible by chemical reactions that use catalysis.

In many ways, catalytic processes and technologies make modern living possible. Reduced emissions in modern cars, pharmaceutical breakthroughs that improve health, increased yield in food production and energy-saving laundry detergents are all made possible by chemical reactions that use catalysis.

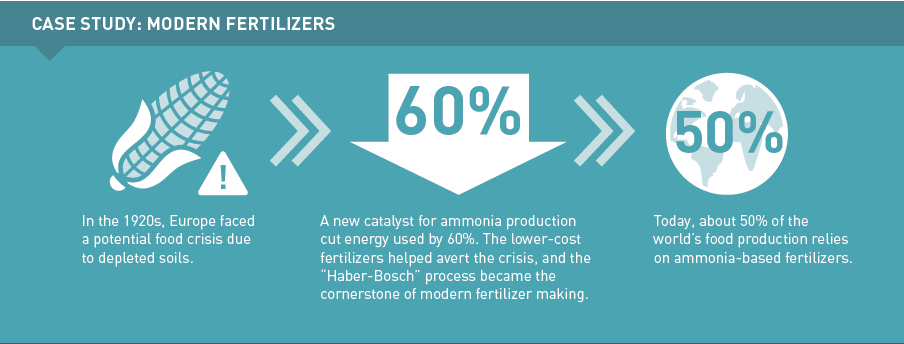

The “Haber-Bosch” process revolutionized agriculture in the early 1900s:

The chemical industry has been a pioneer in the development of catalytic technologies. Today, about 90% of all chemical processes employ catalysis in production, and there is enormous potential for additional energy savings. Advancements are possible in the areas of feedstock, fuels and production of some high-volume chemicals.

The “shale revolution” is already revitalizing the U.S. chemical industry, and future innovations in catalytic processes can help uncover more efficient ways to convert shale-derived feedstocks into value-added products for chemistry and dependent sectors. Economic benefits could include productivity growth as well as jobs for practitioners in science, technology, engineering and math (STEM). Sustainability benefits could include smarter energy use, lower greenhouse gas emissions and less waste.

R&D needed to capitalize on opportunities

In 2015, the American Chemistry Council (ACC) organized a working group made up of scientists and engineers to study how fundamental hurdles in catalytic technologies and processes have been overcome in the past in order to bring about advancements and societal benefits. Could such breakthroughs be replicated today?

The working group identified a number of research hurdles and opportunities, which are highlighted in this fact sheet, “Chemistry Innovation in Action: Advanced Catalytic Processes to Achieve Energy and Sustainability Goals.”

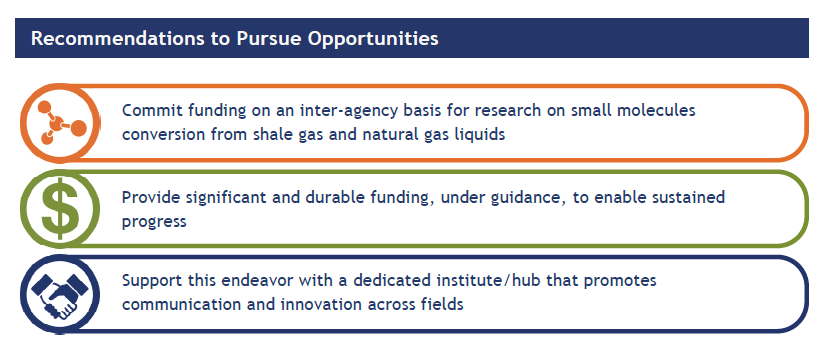

The key takeaway is that “game-changing” advances in catalytic processes and technologies can be achieved, but doing so will require a sustained and coordinated effort among industry, academia and government:

Developing ‘next generation’ catalysis processes will require a dedicated effort over many years. As a first step, support is needed for a multidisciplinary research partnership. - Mike Walls, American Chemistry Council

Catalysis workshop to be held next month

Catalysis workshop to be held next month

The National Academies of Sciences, Engineering, and Medicine will hold a workshop on March 7-9, 2016, “The Changing Landscape of Feedstocks for Chemical Production: Implications for Catalysis.” It will be a great opportunity to explore the areas that R&D efforts should focus on. The workshop is co-sponsored by ACC.

>>See infographic https://www.americanplasticscouncil.org/Policy/Energy/Energy-Efficiency/Catalysis-Infographic.pdf

>>See fact sheet https://www.americanplasticscouncil.org/Policy/Energy/Energy-Efficiency/Advanced-Catalytic-Processes-to-Achieve-Energy-Goals.pdf