Recent tragic events involving chemical facilities have brought to light some important facts about chemical facility safety and security.

Recent tragic events involving chemical facilities have brought to light some important facts about chemical facility safety and security.

Chief among them: nothing is more important to chemical manufacturers than the safety and security of their employees, contractors and the communities in which they work every day.

A commitment to Responsible Care®

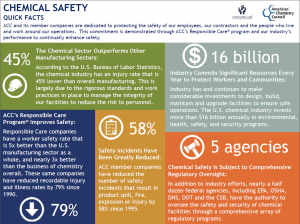

ACC members have demonstrated their commitment to safety performance by adopting the Responsible Care program, the chemical industry’s world-class environmental, health, safety and security performance initiative.

Under the program, ACC members commit to make continual progress toward a goal of no accidents, injuries or harm to human health and the environment from products and operations, and to work with emergency responders and communities to coordinate response plans.

A culture of safety yields measurable results

The men and women of the chemical industry have worked hard to develop a culture that has put our industry at the forefront of manufacturing when it comes to safety.

As the AP’s Jeff Amy recently reported, “It might be easy to conclude that working in a chemical plant is a dangerous occupation, but statistics say otherwise”:

Nationwide, 3.8 of every 100 full-time workers was injured in 2011, according to the U.S. Occupational Safety and Health Administration. The injury rate was 2.4 in the overall chemical manufacturing sector, and 0.6 in the area of chemical manufacturing including the Williams plant [in Louisiana]. That’s among the very lowest injury rate of any manufacturing sector.

And, members of ACC have sought to build upon the overall industry’s safety performance through Responsible Care®, the chemical industry’s world-class environmental, health, safety and security performance initiative. Under Responsible Care, ACC members work with emergency responders and communities to coordinate response plans and to continually improve industry performance.

The results of the program speak for themselves. ACC member companies operate 1,550 facilities nationwide and have an employee safety record that is five times better than the average of the U.S. manufacturing sector as a whole, and more than three times better than the business of chemistry overall. They also have reduced the number of safety incidents that resulted in a product spill, fire, explosion or injury by 58 percent since 1995.

We are very proud of the fact that the worker injury rate for the chemical sector is among the lowest of any manufacturing sector. But we will not stop there.

Safety demands continuous improvement

ACC is working with our members to make improvements to the Responsible Care program with the addition of the Process Safety Code, which is intended to enhance operational safety throughout member company operations.

We are also forging strong partnerships among industry and the government, including Occupational Safety and Health Administration (OSHA) and the Chemical Safety Board (CSB) and other industry organizations, to improve the effectiveness of regulations, as well as look for better ways to share best practices and lessons learned.

And we continue support the numerous federal programs in place that regulate the safe operation of chemical facilities, and believe that agencies should have the appropriate resources to effectively enforce regulations. We believe individual companies have an obligation to understand which laws and regulations they are subject to and take appropriate action to comply.

We recently sent a letter to Congress reaffirming our commitment to work with government officials and industry organizations to advance safety, so we can continue to provide the essential benefits of chemistry to society, while providing good jobs and supporting economic growth.